Views: 0 Author: Site Editor Publish Time: 2025-05-27 Origin: Site

Non-invasive level meters changed industrial processes in 2025. These smart tools measure liquid levels without damaging containers. Their market value may hit USD 1900.28 million this year. Growth is expected to continue at 3.72% yearly until 2033. Devices like the JC-53LW ultrasonic sensor give exact results. They attach outside containers, keeping things safe and efficient. These modern tools work well, even in tough conditions.

Non-invasive level meters check liquid levels without contact. This keeps them safe and accurate for many industries.

These tools need little care since they have no moving parts. This lowers repair costs and keeps them working longer.

Smart tech, like AI and IoT, helps track levels live. It also predicts problems early, making work smoother.

They are simple to set up, saving time and stopping delays. This makes them a smart and cheap option.

Their strong build works well in tough places. They are great for oil, gas, and medicine industries.

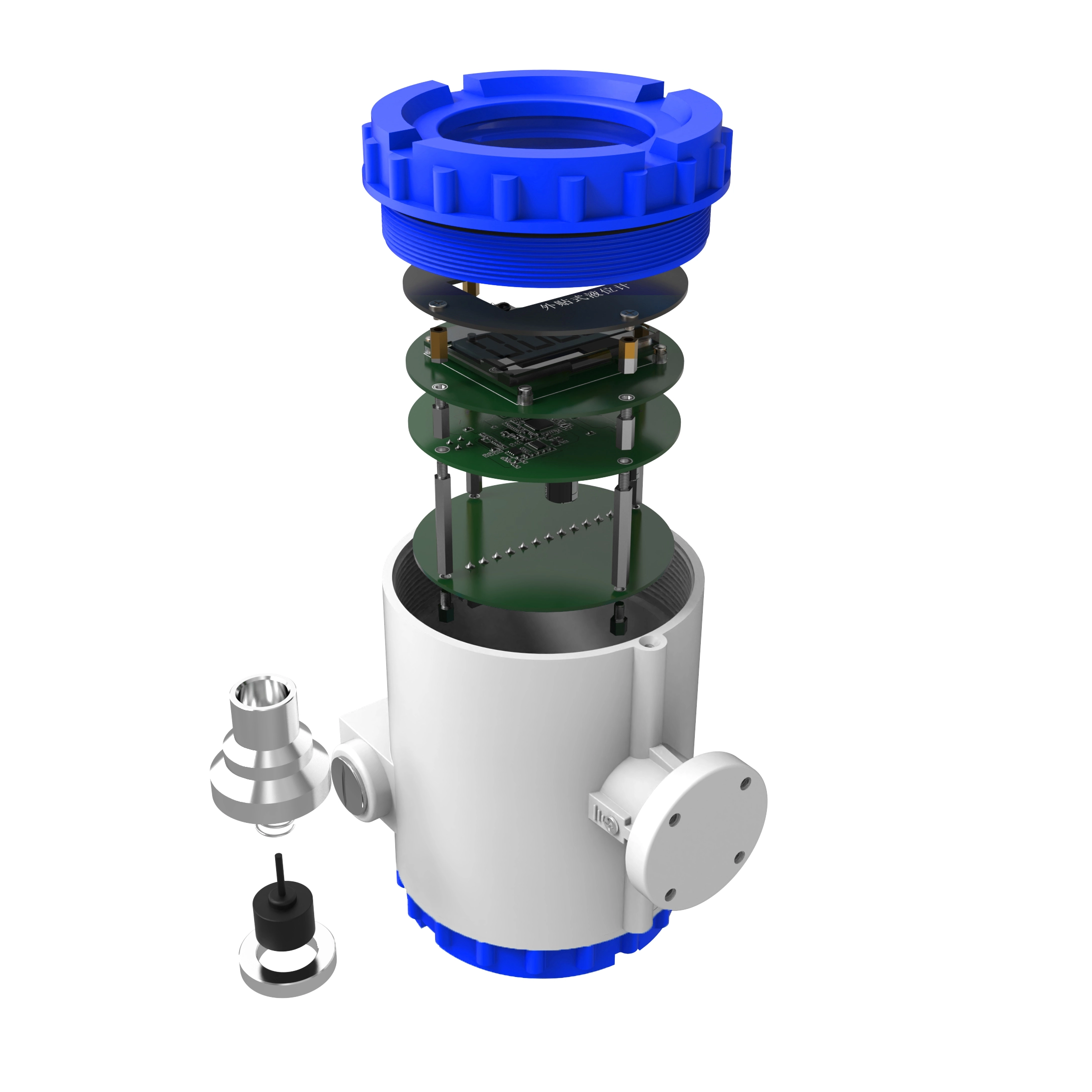

Non-invasive level meters make measuring liquids more accurate. They use sound waves to check levels without touching the liquid. For example, the JC-53LW sensor sends sound waves that bounce off the liquid's surface. It measures the echo to find the exact liquid level.

This method avoids using moving parts, so less fixing is needed. Fast signal processing also improves accuracy, even in dusty or wet places.

Here’s a simple list of what makes these meters so accurate:

Feature | Description |

|---|---|

Measurement Method | Measures without touching, using sound wave technology. |

Maintenance | No moving parts, so it needs little to no fixing. |

Accuracy | Smart chips make liquid level readings very precise. |

Signal Processing | Uses fast signal processing for better and quicker results. |

Operating Conditions | Works well even in tough places with dust or moisture. |

These features make non-invasive level meters perfect for industries needing exact measurements.

AI and IoT have made liquid monitoring easier and smarter. Non-invasive meters now send real-time data and allow remote checks. For example, the JC-53LW sensor connects to systems using RS-485 or HART for smooth communication.

AI studies data to predict repairs and improve performance. IoT lets you check tanks from anywhere, helping you act quickly. Research shows smart systems reduce mistakes and improve efficiency.

Non-invasive level meters are helpful in many fields because they adapt well. They measure liquids without opening containers, keeping things safe and clean. This is especially important in food and medicine industries.

Here’s how different industries use them:

Industry Sector | Application Details |

|---|---|

Water and Wastewater | Tracks water use, finds leaks, and ensures accurate billing. |

Oil and Gas | Measures flow without opening pipes, reducing leaks and contamination. |

Chemical Processing | Safely measures harsh liquids to maintain product quality. |

Power Generation | Monitors water, steam, and other fluids for better performance. |

Food and Beverages | Keeps mixing, dosing, and packaging clean and safe. |

Pharmaceuticals | Measures liquids accurately without contamination during production. |

This flexibility makes non-invasive level meters a must-have for modern industries.

Non-invasive level meters are simple to install. You don’t need to cut pipes or drill containers. Devices like the JC-53LW ultrasonic sensor stick outside, saving time. This design avoids blocking flow, keeping operations smooth.

Follow these tips for best results:

Place sensors on straight pipes with 10D upstream and 5D downstream space.

Install them 30-50 pipe diameters away from inlets.

Keep vibrations under 0.5g RMS and use separate power circuits.

These steps help the meters work well and avoid mistakes. Unlike older methods, non-invasive meters make setup easier, so you can focus on work.

Feature | Description |

|---|---|

Easy Installation | No need to cut pipes |

Low Maintenance | No moving parts, so less fixing is needed |

Better Efficiency | Quick setup and no flow blockages |

Non-invasive level meters need little maintenance. Old systems have moving parts that wear out. These advanced meters use sound waves, so no physical contact is needed. This lowers the chance of breakdowns and keeps performance steady.

A chemical plant study showed ROI in 18 months after using these meters. Less downtime and better efficiency saved money over time. With fewer stops, you can keep working and meet goals easily.

Non-invasive level meters handle harsh environments. They resist extreme heat, moisture, and dust. For example, the JC-53LW sensor is explosion-proof and has IP67 protection. This makes it great for industries like oil and gas, where safety matters.

Unlike old methods, these sensors give real-time data without risking worker safety. You can check liquid levels from a distance, staying safe and accurate. Whether dealing with chemicals or high pressure, these meters give dependable results.

Metric | Traditional Methods | Level Sensor Devices |

|---|---|---|

Accuracy | ±1-5% (float and dye markers) | Up to ±0.1% (ultrasonic and radar) |

±0.5% to ±1% (mechanical gauges) | Up to ±0.2% (capacitance sensors) | |

Reliability | Needs frequent maintenance | Rarely needs maintenance |

Efficiency in Data | Limited data collection | Real-time data and analysis |

Cost Analysis | High costs due to repairs | Saves money with less downtime |

Non-invasive level meters last a long time. They don’t have moving parts that wear out like older systems. This means fewer replacements, saving money over time. For example, the JC-53LW sensor uses sound waves to measure levels. It stays accurate without touching liquids, avoiding mechanical damage.

These meters also handle tough conditions like heat and moisture. Their sturdy design keeps them safe in harsh places. By choosing durable tools, you spend less on repairs and replacements. This helps your work stay smooth and steady.

Non-invasive level meters keep your work running. Unlike older systems, they install without stopping operations. Clamp-on meters attach outside pipes, so production doesn’t pause. This is helpful for industries like paper-making, where stopping work costs money.

Here’s how they save money:

They need little fixing, lowering repair costs.

Maintenance-free designs, like radar systems, work reliably.

Accurate readings in tough spots reduce waste and improve efficiency.

By avoiding downtime, you save money and boost productivity at work.

Non-invasive level meters help cut energy costs. They track energy use in real-time, showing where waste happens. For example, they link energy use to production, helping you improve processes.

Some systems shut machines off during idle times, saving power. This feature reduces utility bills and saves money. Using energy-smart tools also supports eco-friendly practices.

With their accuracy, durability, and energy savings, these meters are a smart choice for modern industries.

Non-invasive level meters, like the JC-53LW ultrasonic sensor, stand out in 2025. Their advanced technology and easy use make them popular. These tools give precise readings and work reliably in industries. Workers say they save time and improve safety rules. One manager shared that safety problems stopped after using remote monitoring. Buying these devices saves money and boosts safety over time. They help keep liquid storage safe and under control.

Benefits Overview:

Better Safety

Accurate Measurements

Low Maintenance

Non-invasive level meters check liquid levels without touching them. They also don’t change the container, which avoids contamination. These meters use advanced sound technology for accurate results. They work well even in tough conditions. Their strong build and easy use make them a better option.

Yes! Tools like the JC-53LW ultrasonic sensor are explosion-proof. They are also rated IP67 for safety. These meters work in heat, moisture, and dusty places. You can check levels from far away, staying safe and accurate. This makes them great for oil, gas, and chemical industries.

Non-invasive meters last longer and need little fixing. They install easily without stopping work, saving downtime costs. These meters also track energy use to improve efficiency. Over time, these savings make them a smart and cost-effective choice.

Yes! You can set them up without cutting pipes or drilling. For example, the JC-53LW sensor sticks outside containers, saving time. Just follow simple steps like placing them on straight pipes. Avoid vibrations for the best results. This simple setup makes them easy to use.

Many industries use these meters, such as:

Water and Wastewater: Finds leaks and ensures correct billing.

Food and Beverages: Measures liquids safely and cleanly.

Pharmaceuticals: Tracks liquids without contamination.

Their flexibility makes them useful in many fields.

Tip: Pick a meter that fits your industry’s needs for the best results.